- Elevator Electric Components

- Elevator Traction Machine

- Elevator Control System

- MONARCH Control Cabinet

- MONARCH Inverter

- MONARCH Car Top Inspection Box

- MONARCH Pit Inspection Box

- STEP Control Cabinet

- STEP Inverter

- STEP Car Top Inspection Box

- STEP Pit Inspection Box

- YASKAWA Control Cabinet

- YASKAWA Inverter

- HAYASHIMU Control Cabinet

- HAYASHIMU Inverter

- HAYASHIMU Car Top Inspection Box

- HAYASHIMU Pit Inspection Box

- Elevator Door System

- Elevator Guide Rail & Balance System

- Elevator Safety Components

- Other Elevator Parts

- Escalator Spare Parts

XIZI GETM3.0H Gearless Elevator Motor | Gearless PMS Traction Motor

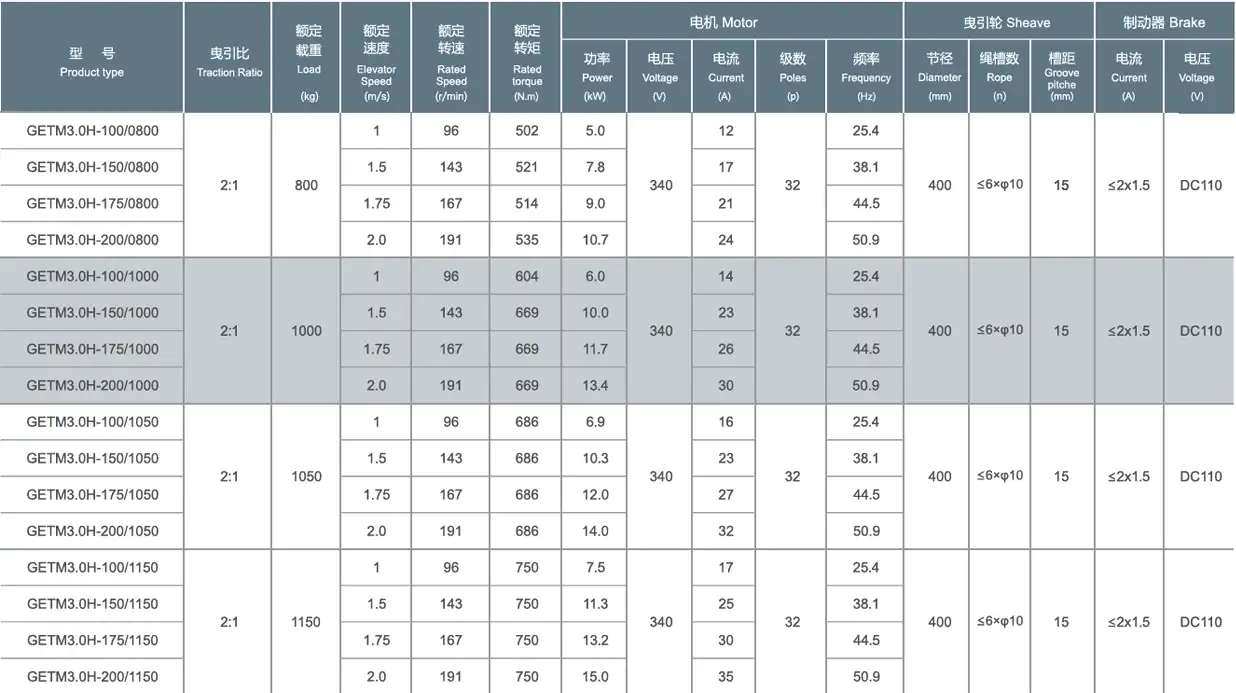

Specifications:

| Feature | Specification |

|---|---|

| Speed Range | 1.0–1.75 m/s |

| Load | 800–1050 kg |

| Power Range | 5–11.7 kW |

| Weight | 290KG |

| Ins. Class | 155(F) |

| Start Up Time | 180 |

| Brake Type | 2×DZD2 |

Categories: Elevator Traction Machine, XIZI Traction Machine

Tags: GETM3.0 PRO, XIZI TRACTION MOTOR

Description

Description

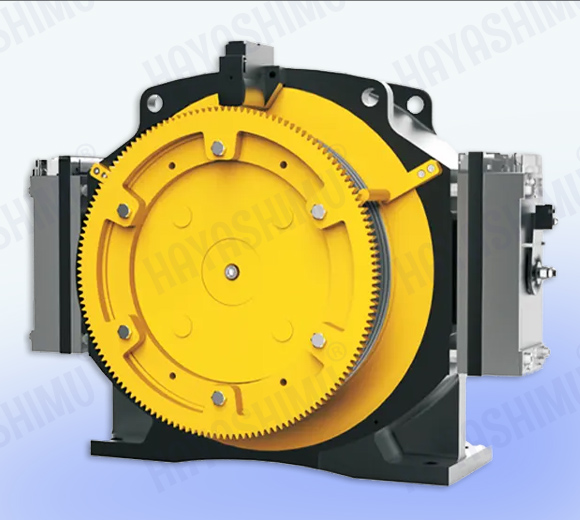

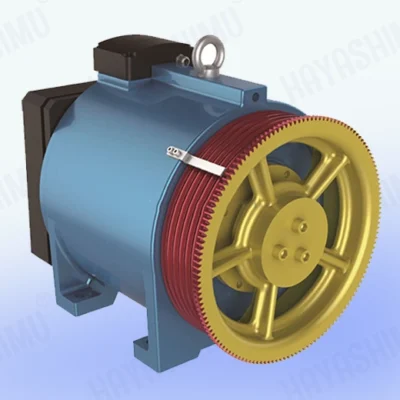

XIZI GETM3.0H Gearless Elevator Motor | Gearless PMS Traction Motor

XIZI GETM3.0H Gearless Elevator Motor | Gearless PMS Traction Motor, the pinnacle of modern vertical transportation technology designed to redefine efficiency, reliability, and passenger experience. This advanced Permanent Magnet Synchronous (PMS) traction motor represents a significant leap forward from traditional geared systems, eliminating the mechanical complexity, energy losses, and maintenance demands associated with gearboxes and worm gears. As urban infrastructure grows skyward and the demand for smarter, more sustainable building solutions intensifies, this gearless motor provides the core power for the next generation of elevators.

The fundamental innovation of the XIZI GETM3.0H lies in its gearless, direct-drive design. By integrating high-strength permanent magnets and a sophisticated drive controller, the motor applies torque directly to the elevator traction sheave. This removal of the intermediary gearbox eliminates a major source of friction, noise, and vibration. The result is a near-silent operation and a ride quality of unparalleled comfort that passengers will immediately notice. Furthermore, the compact and lightweight architecture of the PMS motor allows for greater design flexibility in the machine room or hoistway, often enabling space savings or the use of smaller, more efficient machines.

Energy efficiency is a cornerstone benefit of this gearless PMS traction motor. Traditional geared motors operate with efficiencies typically between 50-70%, with substantial energy lost as heat in the gearbox and motor windings. In contrast, the GETM3.0H achieves peak efficiencies exceeding 90%, especially during partial-load conditions which represent most elevator operation. This dramatic improvement translates directly to lower electricity bills for building owners and a reduced carbon footprint for the property. When integrated with regenerative drive technology, the motor can even feed energy back into the building’s grid during braking cycles, turning a passive load into an active contributor to building energy management. This makes the motor a critical component for projects targeting green building certifications like LEED or BREEAM.

The application of the GETM3.0H extends across the entire spectrum of elevator types. It is perfectly suited for mid to high-rise traction elevator systems, providing the consistent torque and speed control required for smooth, high-performance travel. Its reliability and precision also make it an excellent choice for hospital elevators, where smooth operation is critical for patient comfort and equipment safety. For modernizations, retrofitting an existing hoistway with a gearless PMS system like the GETM3.0H is one of the most impactful upgrades available. It can breathe new life into an older system, dramatically improving ride quality, reducing noise, cutting energy use by up to 40-50%, and virtually eliminating the need for gear oil changes and gear-related repairs.

From a technical perspective, the GETM3.0H features a high-torque, low-speed design optimized for elevator duty cycles. Its permanent magnet rotor provides instant magnetic force, enabling faster response times from the drive controller for superior control of acceleration, deceleration, and leveling. Advanced thermal management ensures stable performance even during peak traffic periods. The motor is designed to work seamlessly with modern Variable Voltage Variable Frequency (VVVF) drives, which provide the intelligent control needed to optimize every aspect of its performance, from torque ripple minimization to advanced destination dispatch coordination.

Choosing the GETM3.0H Gearless Elevator Motor is a forward-thinking investment in performance, sustainability, and total cost of ownership. It represents the industry’s shift towards smarter, cleaner, and more reliable vertical mobility solutions. By eliminating the gearbox, it eliminates a primary point of failure, ensuring decades of dependable service with minimal intervention.

Key Features & Benefits of XIZI GETM3.0H :

-

Gearless Direct-Drive Design: Eliminates the gearbox, reducing noise, vibration, maintenance, and energy losses for superior efficiency and ride comfort.

-

Permanent Magnet Synchronous (PMS) Technology: Delivers high torque density, precise speed control, and exceptional partial-load efficiency exceeding 90%.

-

Substantial Energy Savings: Can reduce elevator system energy consumption by 40-50% compared to traditional geared systems, with regenerative drive compatibility.

-

Low Lifetime Maintenance: Fewer moving parts mean no gear oil changes, reduced wear, and significantly lower long-term operating costs.

-

Compact & Lightweight Form Factor: Enables more flexible machine room layouts and is ideal for both new installations and modernization projects.

-

Smooth & Precise Performance: Provides passengers with an exceptionally quiet, comfortable ride with accurate floor leveling, enhancing the overall building experience.

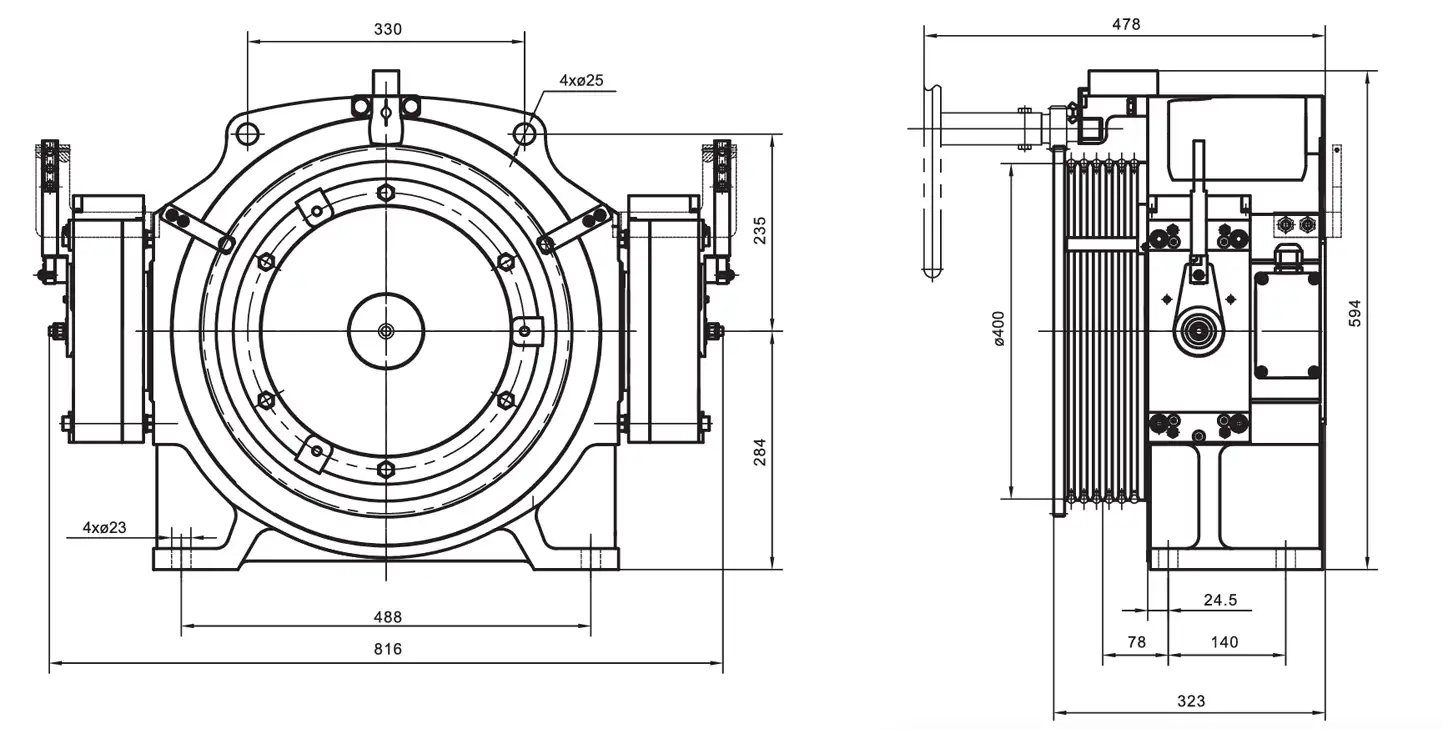

Dimensions:

Technical Data: