- Elevator Electric Components

- Elevator Traction Machine

- Elevator Control System

- MONARCH Control Cabinet

- MONARCH Inverter

- MONARCH Car Top Inspection Box

- MONARCH Pit Inspection Box

- STEP Control Cabinet

- STEP Inverter

- STEP Car Top Inspection Box

- STEP Pit Inspection Box

- YASKAWA Control Cabinet

- YASKAWA Inverter

- HAYASHIMU Control Cabinet

- HAYASHIMU Inverter

- HAYASHIMU Car Top Inspection Box

- HAYASHIMU Pit Inspection Box

- Elevator Door System

- Elevator Guide Rail & Balance System

- Elevator Safety Components

- Other Elevator Parts

- Escalator Spare Parts

XIZI GETM3.0G GETM3.5G Gearless Traction Machine

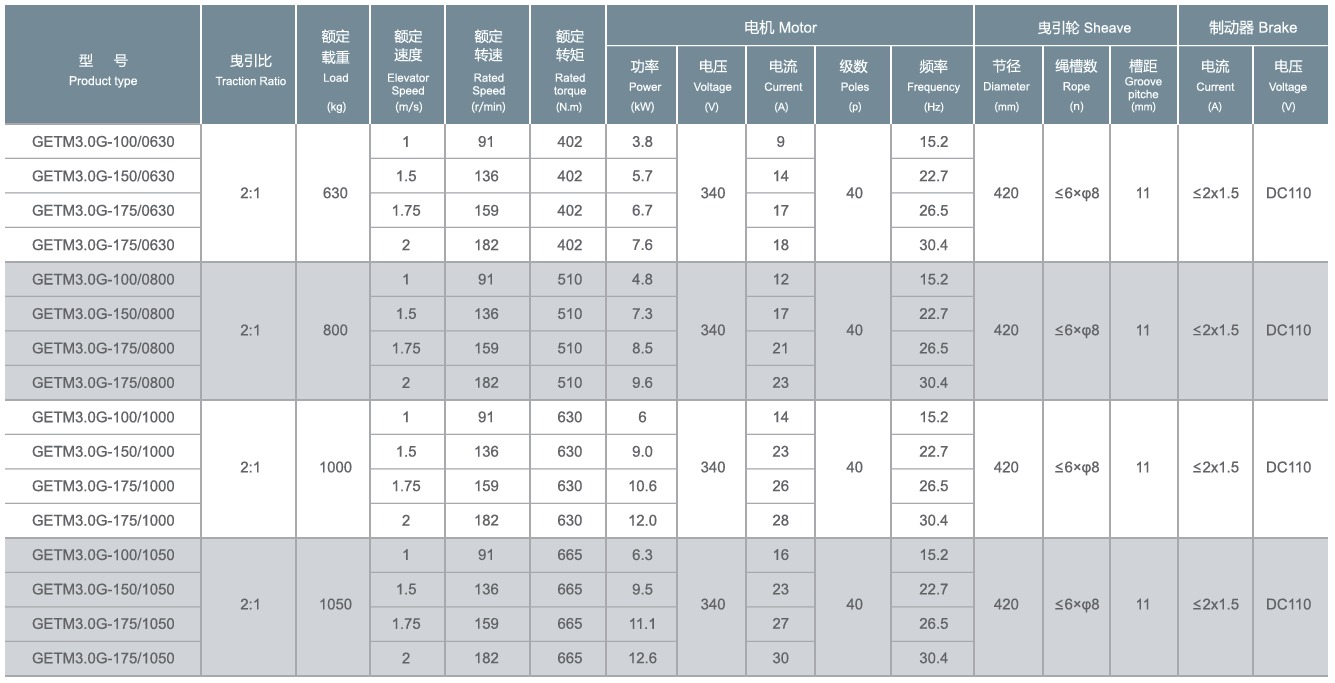

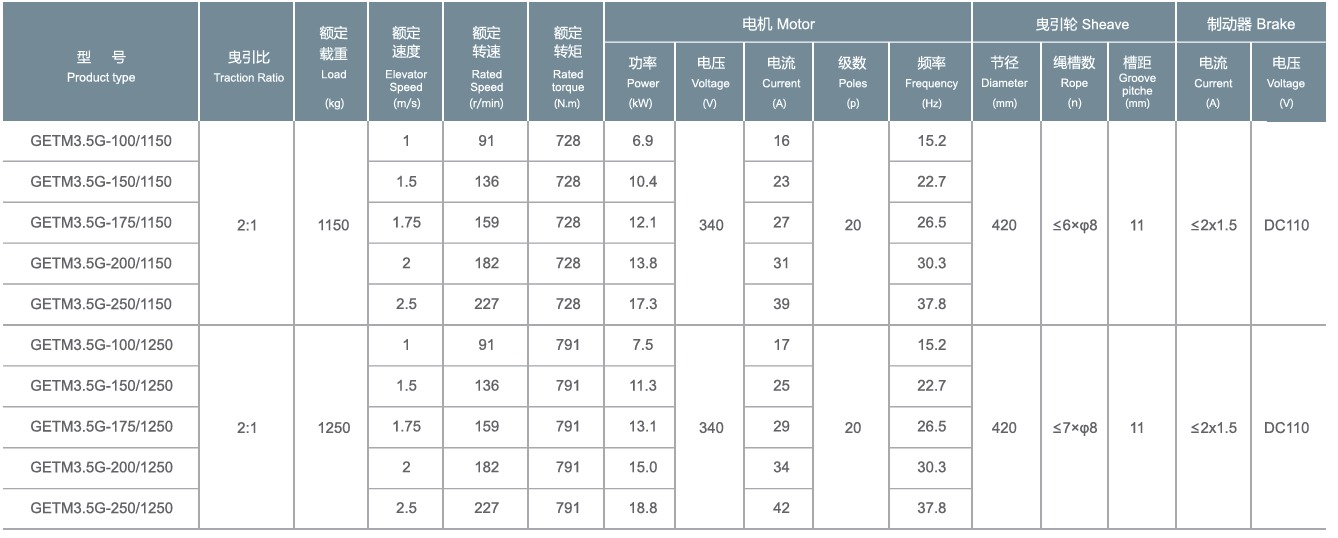

Specifications:

| Feature | Specification |

|---|---|

| Speed Range | 1.0–2.5 m/s |

| Load | 630–1250 kg |

| Power Range | 3.8–18.8 kW |

| Weight | 340KG |

| IP Code | IP41 |

| Start Up Time | 180 |

| Brake Type | 2×DZD2 |

Categories: Elevator Traction Machine, XIZI Traction Machine

Description

Description

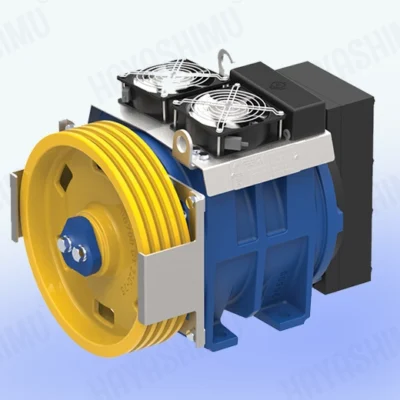

XIZI GETM3.0G | GETM3.5G Gearless Traction Machine

XIZI GETM3.0G and GETM3.5G Gearless Traction Machines, a superior class of permanent magnet synchronous motors engineered to set the performance standard for modern mid-rise commercial and residential elevator systems. These gearless traction machines eliminate the traditional worm gearbox, representing a fundamental leap in efficiency, reliability, and ride quality over conventional geared elevator drives. As building owners and developers increasingly prioritize sustainable operations, occupant comfort, and lifecycle cost savings, the GETM3.0G and higher-capacity GETM3.5G provide the optimal electro-mechanical heart for new installations and modernization projects. Designed for seamless integration with advanced control systems, they deliver the precise motion control, energy savings, and quiet operation required for demanding, high-traffic environments such as office buildings, luxury apartments, hotels, and institutional facilities.

The core innovation of this gearless traction machine series lies in its direct-drive permanent magnet synchronous motor technology. By removing the mechanical gearbox, the system eradicates associated inefficiencies, including gear friction, oil churning losses, and the audible noise of meshing gear teeth. This results in a dramatic improvement in overall system efficiency, with the GETM3.0G and GETM3.5G achieving operational efficiencies exceeding 90%, even during partial-load conditions common in elevator operation. The direct connection between the motor rotor and the traction sheave ensures power is transferred smoothly and directly, enabling exceptionally precise control over acceleration, deceleration, and floor leveling. Passengers experience a sensation of flawless, silent glide—a hallmark of premium building quality that enhances tenant satisfaction and property value.

Energy efficiency is a paramount economic and environmental benefit of adopting these gearless traction machines. Compared to traditional geared systems, which can waste over 40% of input energy as heat and noise, the GETM3.0G and GETM3.5G can reduce a elevator system’s energy consumption by up to 50%. When paired with a regenerative drive, the motor can act as a generator during braking cycles, converting the elevator’s potential energy into clean electricity that is fed back into the building’s power grid. This regenerative capability transforms the elevator from a passive energy consumer into an active energy contributor, significantly lowering net electricity costs and supporting goals for green building certifications like LEED, BREEAM, or WELL. The reduction in heat output also decreases the cooling load on the machine room, allowing for smaller, more efficient HVAC systems.

From a technical and maintenance perspective, the gearless design offers substantial long-term advantages. The simplification of the drive train to primarily the motor, sheave, and brake means there are far fewer components subject to wear. The elimination of gear oil removes a recurring maintenance task and the associated environmental disposal concerns. This leads to dramatically reduced lifetime maintenance costs and increased machine reliability, maximizing elevator uptime—a critical factor for commercial properties. The compact and lightweight design of these machines, particularly the GETM3.0G, provides greater flexibility in machine room layout and can even enable the elimination of a dedicated machine room in some MRL (Machine-Room-Less) configurations, freeing up valuable leaseable space.

The XIZI GETM3.0G and GETM3.5G are specifically engineered to cater to a range of mid-rise applications. The GETM3.0G is ideally suited for lighter duty cycles or moderate speeds and loads, perfect for low-to-mid rise residential or commercial buildings. The GETM3.5G, with its enhanced power and torque capacity, is designed for more demanding applications requiring higher speeds, greater lifting capacity, or more intensive duty cycles, such as busy office buildings or upscale hotels. This scalable solution ensures specifiers can select the perfect machine to match the specific kinematic requirements (speed, load, travel height) of any project, ensuring optimized performance and cost-effectiveness.

Investing in the XIZI GETM3.0G or GETM3.5G Gearless Traction Machine is an investment in future-proof building infrastructure. It delivers an immediate improvement in passenger experience, provides ongoing operational savings through unmatched energy efficiency, and ensures decades of reliable service with minimal maintenance intervention.

Key Features & Benefits:

-

Gearless Permanent Magnet Synchronous Design: Eliminates the inefficient gearbox, delivering superior efficiency (>90%), silent operation, and a perfectly smooth ride.

-

Substantial Energy Savings: Reduces elevator energy consumption by up to 50% compared to geared systems, with regenerative drive compatibility for further savings.

-

Low Lifetime Maintenance: No gear oil changes, reduced wear parts, and simplified mechanics lead to minimal upkeep and maximized elevator uptime.

-

Compact & Flexible Installation: Lightweight and space-efficient design enables versatile machine room layouts and is ideal for MRL (Machine-Room-Less) applications.

-

Precision Motion Control: Enables flawless acceleration, deceleration, and leveling accuracy for ultimate passenger comfort and accessibility.

-

Scalable Model Range: The GETM3.0G and higher-capacity GETM3.5G provide optimized solutions for a wide spectrum of mid-rise commercial and residential elevator needs.

Technical Data:

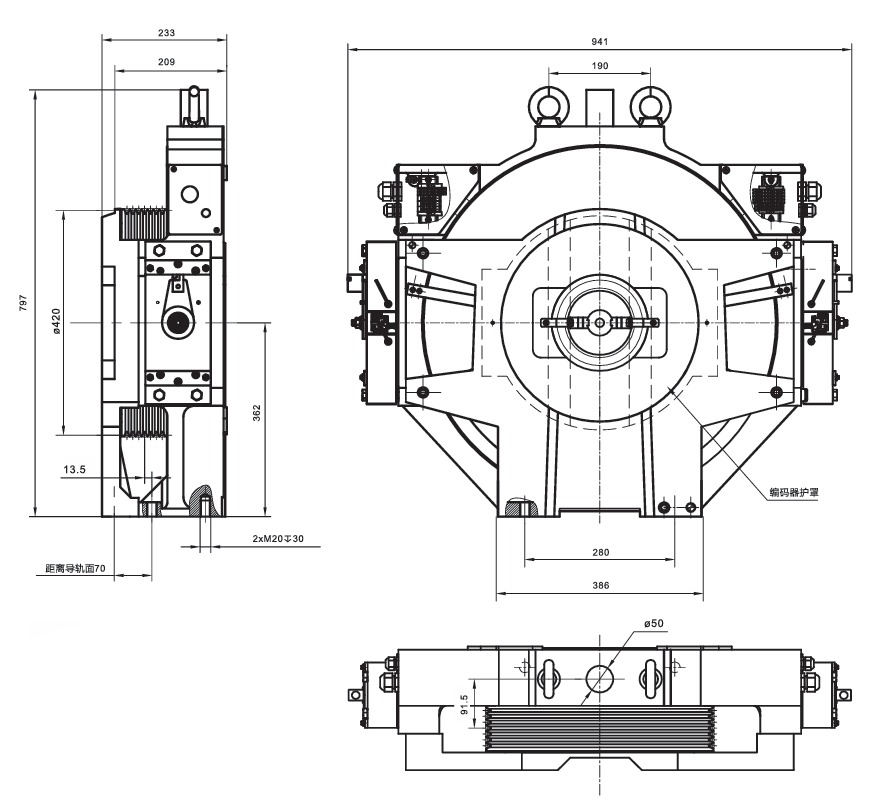

Dimensions: