- Elevator Electric Components

- Elevator Traction Machine

- Elevator Control System

- MONARCH Control Cabinet

- MONARCH Inverter

- MONARCH Car Top Inspection Box

- MONARCH Pit Inspection Box

- STEP Control Cabinet

- STEP Inverter

- STEP Car Top Inspection Box

- STEP Pit Inspection Box

- YASKAWA Control Cabinet

- YASKAWA Inverter

- HAYASHIMU Control Cabinet

- HAYASHIMU Inverter

- HAYASHIMU Car Top Inspection Box

- HAYASHIMU Pit Inspection Box

- Elevator Door System

- Elevator Guide Rail & Balance System

- Elevator Safety Components

- Other Elevator Parts

- Escalator Spare Parts

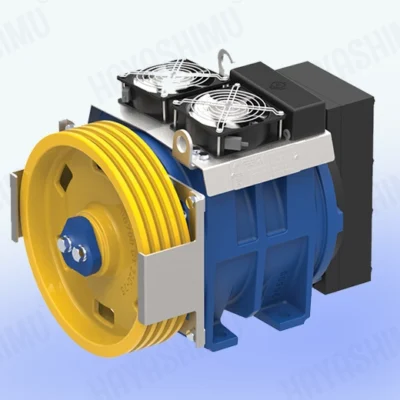

FUJI JAPAN Elevator Traction Machine | Japan Technology

Specifications:

| Parameter | Specification |

|---|---|

| Speed Range | 1–1.75 m/s |

| Rated Load | 450–630 kg |

| Power Range | 4.1–7.2 kW |

| Voltage | 3P 340V±10% 50/60Hz |

Categories: Elevator Traction Machine, FUJI Japan Traction Motor

Description

Description

FUJI JAPAN Elevator Traction Machine | Japan Technology

FUJI JAPAN Elevator Traction Machine is a benchmark of Japanese engineering excellence, crafted by Fuji since 1959 with over 60 years of expertise in lifting system innovation. As the necessity of electric transport grows globally, this traction machine aligns seamlessly with electric bikes, rickshaws, and auto rickshaws, forming a holistic sustainable mobility ecosystem. While electric three-wheelers transform ground travel, FUJI’s gearless design elevates vertical transport standards, embodying Japan’s reputation for precision, reliability, and eco-conscious engineering.

Designed for residential, commercial, and small cargo elevators, this Japanese traction machine embodies the core values of electric transport: efficiency and sustainability. Its gearless permanent magnet synchronous structure eliminates gear mechanical loss, cutting energy consumption by 33% compared to traditional models . This mirrors how electric rickshaws reduce city pollution, as the FUJI Traction machine operates with zero oil pollution, minimal vibration, and ultra-quiet performance—critical for dense urban areas where livability and environmental responsibility are paramount.

Technical Specifications:

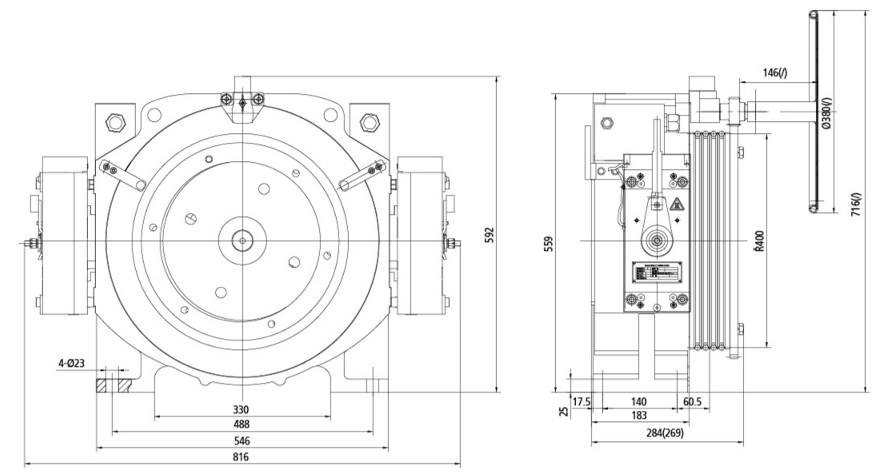

Dimensions:

Key Features & Benefits:

-

Japanese Precision Engineering: Manufactured under Japan’s legendary quality standards for unmatched reliability, durability, and performance consistency.

-

Permanent Magnet Synchronous Motor (PMSM): Delivers maximum energy efficiency, superior torque control, and silent operation in a gearless direct-drive system.

-

Exceptional Energy Savings: Reduces hoisting energy consumption by 40-50% and offers full regenerative drive compatibility for sustainable operation.

-

Ultra-Low Maintenance & High Uptime: Gearless, oil-free design minimizes routine upkeep, lowers lifetime costs, and ensures exceptional system availability.

-

Unrivaled Ride Quality: Provides a perfectly smooth, whisper-quiet passenger journey with impeccable comfort and landing precision.

-

Universal Application: Expertly suited for both Machine Room-Less (MRL) and traditional Machine Room (MR) configurations in all building types.