- Elevator Electric Components

- Elevator Traction Machine

- Elevator Control System

- MONARCH Control Cabinet

- MONARCH Inverter

- MONARCH Car Top Inspection Box

- MONARCH Pit Inspection Box

- STEP Control Cabinet

- STEP Inverter

- STEP Car Top Inspection Box

- STEP Pit Inspection Box

- YASKAWA Control Cabinet

- YASKAWA Inverter

- HAYASHIMU Control Cabinet

- HAYASHIMU Inverter

- HAYASHIMU Car Top Inspection Box

- HAYASHIMU Pit Inspection Box

- Elevator Door System

- Elevator Guide Rail & Balance System

- Elevator Safety Components

- Other Elevator Parts

- Escalator Spare Parts

FUJI Gearless Traction Machine | Peak Performance

Specifications:

| Parameter | Specification |

|---|---|

| Speed Range | 1.0–1.75 m/s |

| Rated Load | 800–1000 kg |

| Power Range | 5–11.7 kW |

| Voltage | 3P 340V±10% 50/60Hz |

Categories: Elevator Traction Machine, FUJI Japan Traction Motor

Description

Description

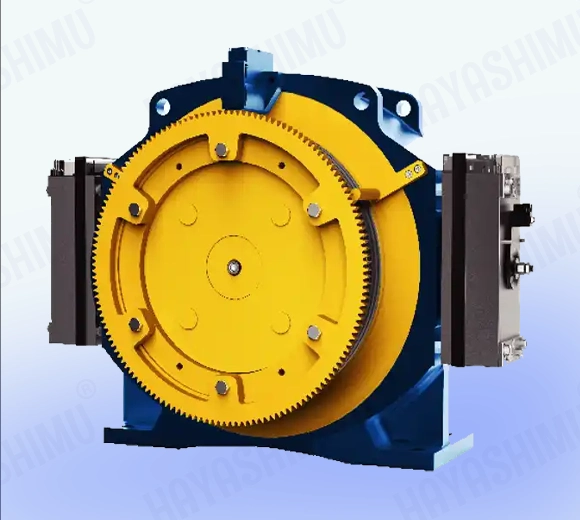

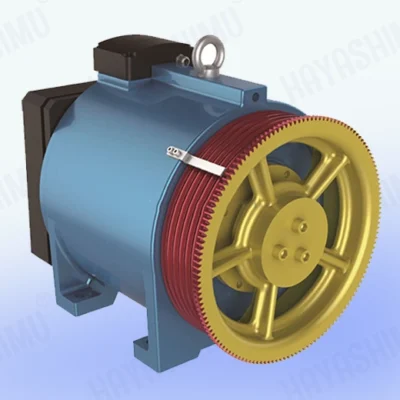

FUJI Gearless Traction Machine | FUJI JAPAN

FUJI Gearless Traction Machine | FUJI JAPAN, the definitive fusion of legendary Japanese precision and cutting-edge gearless elevator technology. This advanced Permanent Magnet Synchronous Motor (PMSM) traction machine is engineered to set the global standard for reliability, energy efficiency, and silent operation in vertical transportation. Designed under Japan’s rigorous quality protocols, it provides an uncompromising solution for building developers, consultants, and owners who prioritize lifecycle value, superior passenger experience, and sustainable building operations. By integrating a direct-drive, gearless design with the meticulous craftsmanship synonymous with the FUJI name, this traction machine delivers unparalleled performance for both Machine Room-Less (MRL) and traditional Machine Room (MR) applications, serving as the robust and intelligent core for prestigious commercial, residential, and institutional projects worldwide.

The engineering superiority of the FUJI Gearless Traction Machine is anchored in Japan’s heritage of technological excellence and continuous innovation. Each unit is a product of precision manufacturing, where high-density permanent magnets and optimized electromagnetic circuits work in harmony within a direct-drive system. The complete elimination of the traditional worm gearbox is a transformative achievement—it removes inherent sources of energy loss, mechanical noise, vibration, and the ongoing requirement for gear oil maintenance. This results in an elevator system characterized by its whisper-quiet ascent and descent, impeccably smooth acceleration profiles, and flawless floor-leveling accuracy. The passenger experience is one of serene, undisturbed comfort, a direct testament to the Japanese principle of perfection in functionality.

Operational economy and environmental stewardship are central to the machine’s design philosophy. The FUJI gearless system operates at exceptional electro-mechanical efficiencies, often exceeding 90%, which can reduce the elevator’s hoisting energy consumption by 40 to 50% compared to conventional geared units. This dramatic reduction directly lowers a building’s operational expenditure and carbon footprint. When configured with a regenerative drive, the machine captures kinetic energy during braking and converts it into clean, reusable AC power, feeding it back into the building’s electrical system. This capability not only maximizes energy savings but also positions the building favorably for leading green certification programs, aligning with global sustainability goals through superior Japanese engineering.

From a reliability and total cost of ownership perspective, the gearless design philosophy ensures decades of dependable service. The mechanical simplification inherent in removing gears and lubrication systems drastically reduces maintenance needs. There are no gear oil changes, no risk of lubricant leaks, and no gear wear to monitor. This translates to significantly lower long-term maintenance costs, exceptional system uptime, and an extended operational lifespan that protects the capital investment. Built to endure the most demanding duty cycles, the FUJI machine is the trusted choice for critical applications where failure is not an option, including high-traffic metropolitan offices, luxury hotels, advanced medical facilities, and high-rise residential towers.

The application versatility of the FUJI Gearless Traction Machine reflects thoughtful, human-centric design. Its compact and efficient architecture makes it the ideal choice for space-saving MRL installations, freeing valuable building area for revenue-generating or functional purposes. Concurrently, its powerful performance profile and engineered accessibility make it a premier selection for traditional machine room setups. This dual-configuration capability ensures it meets the precise demands of any project, from modernizing historic structures to serving as the foundational technology in new, intelligent skyscrapers. Its native compatibility with digital control systems further enables smart building integration, facilitating IoT connectivity for remote diagnostics, predictive maintenance, and optimized traffic management.

Choosing the FUJI Gearless Traction Machine is an investment in transcendent quality, enduring performance, and operational excellence. It delivers measurable returns through radical energy savings, minimal maintenance, and superior passenger satisfaction, all underscored by the uncompromising standards of Japanese engineering. It is not merely a component but the reliable, high-performance heart of a world-class vertical transportation system, carrying the FUJI JAPAN legacy in every revolution.

Key Features & Benefits:

-

Japanese Engineering by FUJI: Synonymous with legendary precision, unwavering reliability, and globally trusted quality in vertical transportation.

-

Gearless Permanent Magnet Synchronous Motor (PMSM): Delivers peak energy efficiency, superior torque control, and silent, vibration-free direct-drive operation.

-

Exceptional Energy Savings: Reduces hoisting energy consumption by 40-50% and offers full regenerative drive compatibility for sustainable building operation.

-

Zero Maintenance Design: Gearless, oil-free construction eliminates all gear-related upkeep, ensuring maximum uptime and lowest lifetime costs.

-

Ultimate Passenger Comfort: Provides a perfectly smooth, library-quiet journey with impeccable comfort and pinpoint landing accuracy.

-

Universal Configuration Ready: Expertly engineered for both space-saving Machine Room-Less (MRL) and traditional Machine Room (MR) installations.

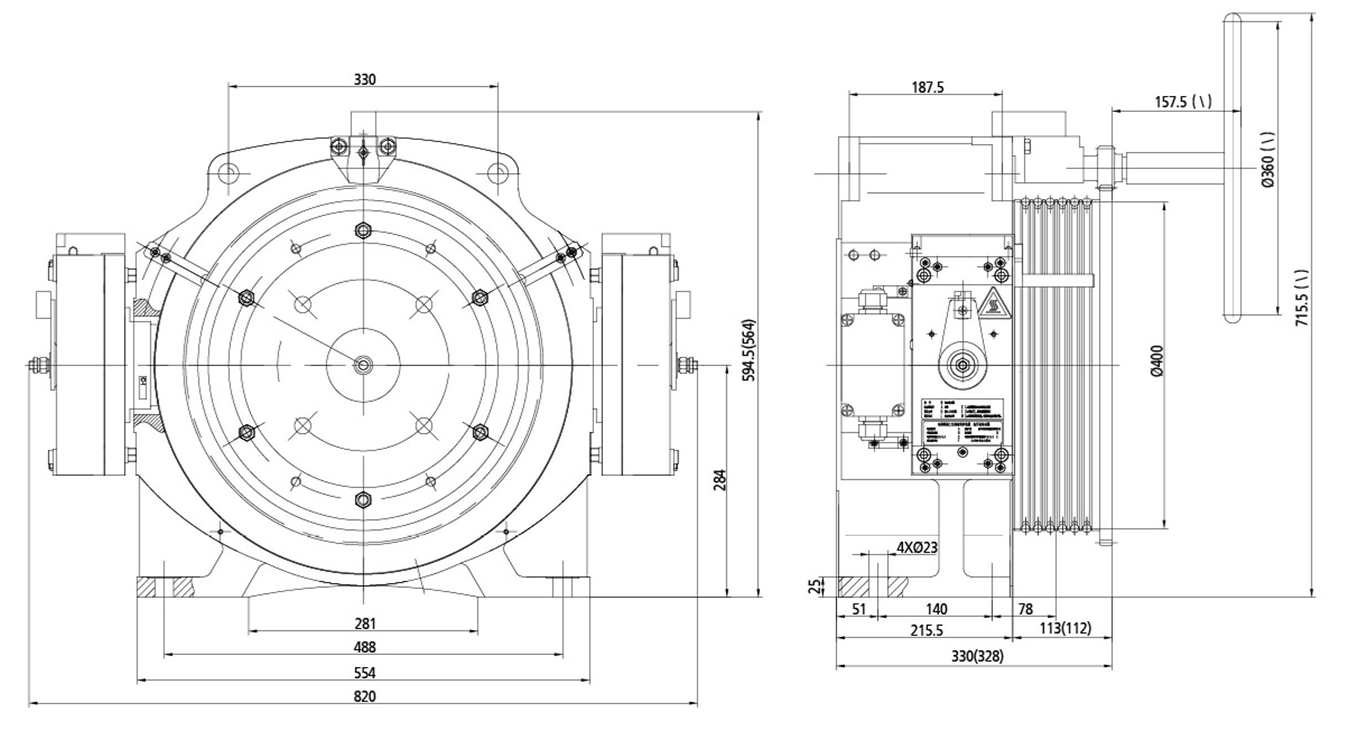

Technical Specifications:

Dimensions: