- Elevator Electric Components

- Elevator Traction Machine

- Elevator Control System

- MONARCH Control Cabinet

- MONARCH Inverter

- MONARCH Car Top Inspection Box

- MONARCH Pit Inspection Box

- STEP Control Cabinet

- STEP Inverter

- STEP Car Top Inspection Box

- STEP Pit Inspection Box

- YASKAWA Control Cabinet

- YASKAWA Inverter

- HAYASHIMU Control Cabinet

- HAYASHIMU Inverter

- HAYASHIMU Car Top Inspection Box

- HAYASHIMU Pit Inspection Box

- Elevator Door System

- Elevator Guide Rail & Balance System

- Elevator Safety Components

- Other Elevator Parts

- Escalator Spare Parts

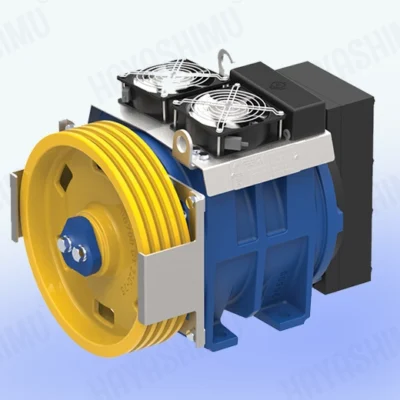

KM Japan Elevator Traction Motor | MRL Traction Motor

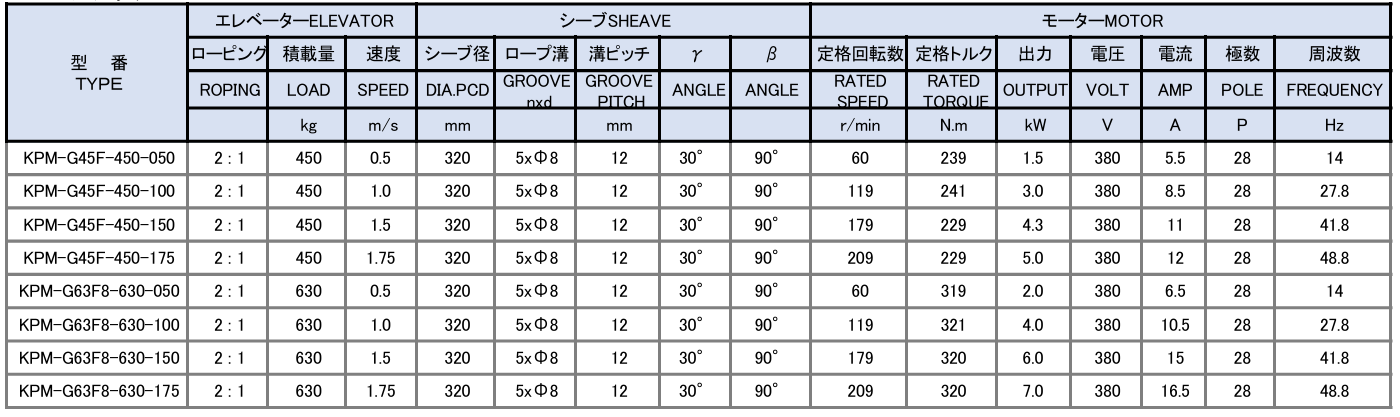

Specifications:

| Parameter | Specifications |

| Rope | 2:1 |

| Speed(m/s) | 0.05-1.75 |

| Load (KG) | 450-630 |

| Motor Weight (KG) | 200 |

| Sheave PCD DIA(mm) | 400 |

| Duty Cycle | S5-60% |

| Brake Type | SDZK-5500JR |

| Brake Torque (N.m) | 2*445 |

| Encoder | HEIDENHAIN ERN1387 |

Categories: Elevator Traction Machine, KM Traction Machine

Tags: KANEKO Traction Machine, KM, Traction machine

Description

Description

KM Japan Elevator Traction Motor | MRL Traction Motor

KM Japan Elevator Traction Motor a premium drive system that embodies Japanese precision engineering for the global vertical transportation market. This advanced Machine Room Less (MRL) traction motor integrates state-of-the-art permanent magnet synchronous technology into a compact, gearless unit designed to be installed directly within the elevator hoistway. It represents the optimal synthesis of reliability, space efficiency, and performance, engineered to meet the rigorous demands of modern commercial, residential, and high-rise applications. By eliminating the traditional overhead machine room, this traction motor delivers significant architectural and cost advantages while providing the exceptionally smooth, quiet, and energy-efficient operation that is the hallmark of superior elevator performance. It is the definitive choice for projects where space optimization, total cost of ownership, and uncompromising quality are paramount.

The core innovation of this Japan-engineered MRL traction motor is its space-optimizing design. The complete elimination of a separate machine room frees up valuable square footage on the building’s rooftop or top floor, allowing architects and developers to reclaim this space for additional leasable areas, residential units, or critical building equipment. This design significantly reduces the overall construction footprint and can lead to material savings in building materials and structural support. The motor itself is a marvel of compact engineering, housing a high-torque, low-speed permanent magnet synchronous motor (PMSM), an integral brake, and a traction sheave in a single, streamlined unit that mounts seamlessly in the hoistway. This approach not only saves space but also simplifies the installation process, reduces material costs, and minimizes the building’s visual impact.

Energy efficiency is engineered into the DNA of this KM Japan traction motor. The gearless, direct-drive permanent magnet technology operates at exceptional efficiency levels, often exceeding 90%, even under partial load conditions which constitute the majority of elevator operation. This stands in stark contrast to the significant energy losses inherent in traditional geared systems due to gear friction and heat generation. The result is a dramatic reduction in the elevator system’s power consumption, typically by 40-50%, directly lowering the building’s operational expenses and carbon footprint. When paired with a regenerative drive, the motor acts as a generator during braking cycles, converting potential energy into clean electricity that is fed back into the building’s grid. This regenerative capability transforms the elevator into an active energy asset, supporting sustainable building certifications and advanced energy management goals.

Performance and reliability are paramount. The absence of a mechanical gearbox removes the primary source of noise, vibration, and wear in conventional systems. Passengers experience a virtually silent and flawlessly smooth journey, with precise control over acceleration, deceleration, and landing accuracy. This superior ride quality enhances the perceived value of the building and improves user satisfaction. From a maintenance perspective, the gearless design is inherently more reliable. With no gear oil to monitor, change, or dispose of, and significantly fewer moving parts subject to wear, the system demands minimal routine upkeep. This design ensures higher operational uptime, reduced lifetime maintenance costs, and long-term operational stability—a key benefit for facility managers and building owners.

The application scope for this high-performance MRL traction motor is extensive. It is ideally suited for mid to high-rise commercial installations, including office towers, hotels, and mixed-use developments where space efficiency and daily reliability are critical. It is equally effective in premium residential complexes where quiet operation is a necessity. Furthermore, its compatibility with modern IoT-enabled control systems allows for smart building integration, enabling features like remote monitoring, predictive maintenance analytics, and optimized traffic management. For modernization projects, retrofitting an outdated system with this advanced KM Japan MRL motor is a transformative upgrade that modernizes performance, drastically cuts energy use, and can potentially recover lost space.

Investing in the KM Japan Elevator Traction Motor is an investment in lasting quality, operational excellence, and architectural flexibility. It delivers immediate benefits in space savings and energy reduction while providing the dependable, high-comfort performance that defines world-class buildings. It represents the intelligent, forward-thinking solution for next-generation vertical mobility.

Key Features & Benefits:

-

Machine Room Less (MRL) Design: Eliminates the dedicated machine room, freeing up valuable architectural space and reducing construction costs.

-

Japanese Precision Engineering: Guarantees exceptional manufacturing quality, reliability, and long-term performance consistency.

-

Gearless Permanent Magnet Motor: Provides superior energy efficiency (>90%), ultra-quiet operation, and a perfectly smooth ride for passengers.

-

Substantial Operational Savings: Reduces energy consumption by 40-50% and minimizes maintenance through an oil-free, low-wear design.

-

Compact & Integrated Unit: Streamlines installation within the hoistway, simplifying construction and enabling more flexible building designs.

-

Ideal for Smart Buildings: Compatible with advanced control and monitoring systems for optimized performance and predictive maintenance.

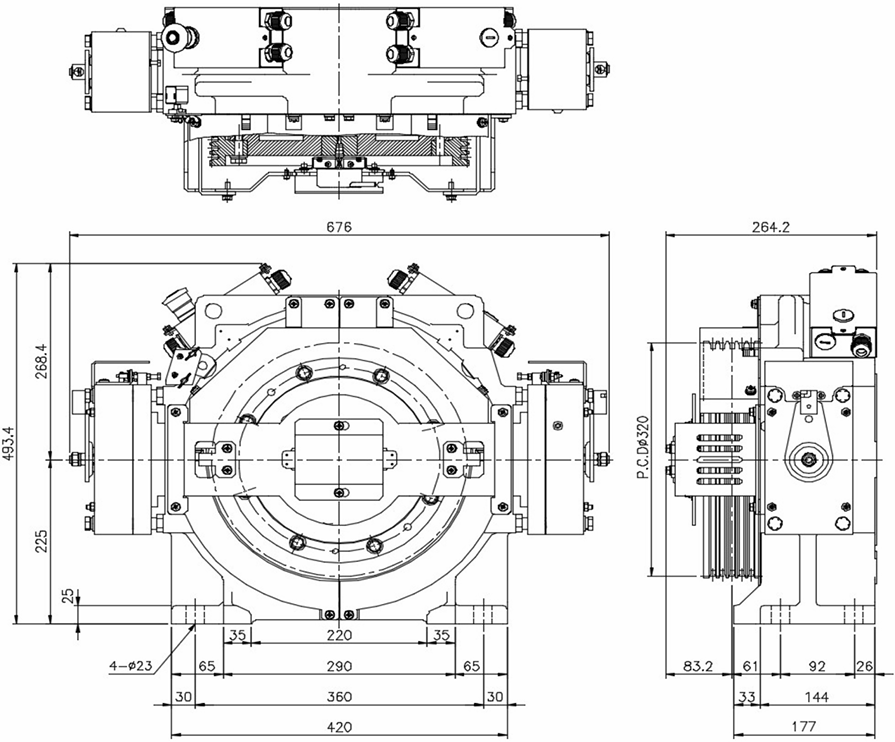

Dimensions:

Technical Specifications: